ball mills coal deficiencies

Modeling on the Effect of Coal Loads on Kinetic Energy of Balls

2015year5month15day To improve the accuracy of the coal load detection based on the kinetic energy of balls in a tubular ball mill, a Discrete Element Method (DEM) model for ball kinematics based on coal loads is proposed. The operating process for a ball mill and the

Үйлчилгээ

Exploring ball size distribution in coal grinding mills

2014year5month1day The amount and ball size distribution in this charge, as well as the frequency with which new balls are added to the mill, have significant effects on the mill capacity

Үйлчилгээ

Modeling and control of ball mill system considering coal moisture ...

2016year8month1day Abstract. This study analyzes the dynamic characteristics of duplex inlet and outlet ball mill direct firing pulverizing system. A mass and energy balance-based model

Үйлчилгээ

Determining Optimum Productivity of a Ball Drum Mill When

2021year2month8day Ball drum mills (BDM) are one of the main types of coal-grinding equipment in Russia. A significant drawback of BDM is high power consumption (a significant part of

Үйлчилгээ

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING

2021year7month31day 2.1 Breakage mechanisms in a ball mill 22 2.2 First order reaction model applied to milling 24 2.3 Grinding rate versus particle size for a given ball diameter 25 ...

Үйлчилгээ

(PDF) Modeling on the Effect of Coal Loads on Kinetic Energy of Balls ...

2015year7month9day To improve the accuracy of the coal load detection based on the kinetic energy of balls in a tubular ball mill, a Discrete Element Method (DEM) model for ball

Үйлчилгээ

Mathematical validation and comparison of ball tube and bowl mill ...

2023year6month7day Mathematical validation and comparison of coal milling operations of a horizontal ball tube mill and a vertical bowl mill located in two distinct coal based power

Үйлчилгээ

Correlation Analysis of Boiler Operation Parameters Based on Mill Ball ...

2015year10month13day The working reliability of ball mill directly affects the reliability of coal pulverizing system and even boiler unit. The correlative degree analysis and balanced

Үйлчилгээ

Exploring ball size distribution in coal grinding mills

2014year5month1day 1. Introduction The expected grinding performance of a mill can be estimated by applying phenomenological grinding kinetic theory that relies on a rate of

Үйлчилгээ

Charge behaviour and power consumption in ball mills:

2001year8month1day Abstract The number of lifters in the liner of ball mills and the mill rotation speed are among the most significant factors affecting the behavior of grinding charge

Үйлчилгээ

ball mills coal deficiencies

Inspections on machinary on sites, report deficiencies to Plant Engineer, improve housekeeping standards Execute of All Plant - Repairs, Maintenance Overhauls and Laser Alingments Gearbox Motors, Screens, Conveyor Drives, Conveyor Structures, Ball Mills, Pump Repairs (Different Makes Models)May 16, 2021 Steam Boiler is a device to

Үйлчилгээ

How coal gets crushed in ball mills? - LinkedIn

2023year11month7day Coal-Fines Separation: The crushed coal is carried away by the air and is separated from the coarser particles in a classifier or separator within the ball mill. Drying: After the coal is crushed ...

Үйлчилгээ

Experimental investigation of vibration signal of an

2008year9month1day The experiments were performed on a tubular ball mill of a 250 MW power plant unit (see Fig. 1).The mill has a diameter of 3.2. m and a length of 4.7 m, and driven by a motor (YTM500-6).. The nominal revolutions per minute (rpm) of this mill was 18.42, and the mill power draft 710 KW.The mill was operated with a combination of three different

Үйлчилгээ

ball mills coal deficiencies - zimmer-hotel

Ball mills coal deficiencies - mahamaham2016 Coal Ball Mill - Great Wall Coal ball mill is the equipment used for grinding and drying coal with different hardness. It is mainly composed of feeding device, principal axis, rotating part.8.3.2.2 Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media.

Үйлчилгээ

A Bond Work index mill ball charge and closing screen

2017year8month10day Several modifications or solutions to Bond's mill ball charge specifications have been proposed (Table 1).Mosher and Tague (2001) recognized the difficulty in making up a mill charge corresponding to Bond's specifications and proposed the use of worn balls from batch, pilot or full-scale ball mills that maintain Bond's specifications. Since the vast

Үйлчилгээ

Modeling and control of ball mill system considering coal moisture ...

2016year8month1day Conclusion. A duplex inlet and outlet ball mill pulverize system model is established by considering the effect of raw coal moisture on the dynamic characteristic of the mill. The EKF approach is employed to estimate and verify the model states, and an extended state space predictive controller is applied to the established model. Simulation ...

Үйлчилгээ

Correlation Analysis of Boiler Operation Parameters Based on Mill Ball ...

2015year10month13day Coal fired boiler includes the combustion system, steam-water system, attemperation system, air and flue gas system, pulverizing system and the soot blower system [].Ball mill is an important part of the combustion system, and the coal pulverizing and treating process is shown in Fig. 1.The coal falling into coal feeder from coal bunker

Үйлчилгээ

en/causes of poor output on coal ball mill.md at main

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Үйлчилгээ

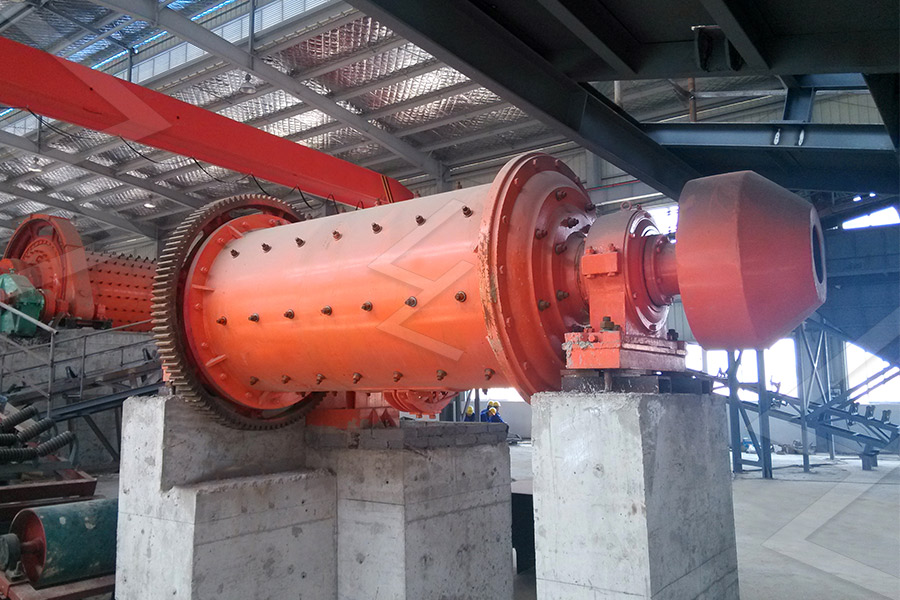

Ball Mill_北方重工 - NHI

Ball mill is the key equipment for grinding materials after they are broken, which is widely used in mineral processing, metallurgy, building materials, chemical industry and other production industries. 2.Parameter Specification. Model:MQY0909~MQY79136. Drum Specification Parameter (Dia. mm×Length mm):900×900~7900×13600. 3. Product ...

Үйлчилгээ

Review of control and fault diagnosis methods applied to coal mills ...

2015year8month1day The control of the coal mills using estimated/measured pulverized fuel flow and level showed promising results and provides opportunity to improve the mill transient operation without much. Conclusion. In this paper, a review of the current state of work done on advanced controls and fault diagnosis for power plant coal mills is presented.

Үйлчилгээ

Modeling and control of ball mill system considering coal moisture ...

2016year8month1day 1. Introduction. Duplex inlet and outlet ball mills are widely used in 200–300 MW coal-fired generating units. This pulverizing system is easily adaptable to multiple coal type and is simple to operate, thus it is suitable for pulverizing coal with low grindability, high abrasiveness and required degree of fineness.

Үйлчилгээ

ball mills coal deficiencies bhansalitrailors in

Ball Mills Coal Deficiencies. The purpose of wrapping ball mills with thermalacoustic blankets is twofold 1 to maintain the desired temperature inside the mill and 2 to reduce the sound emanating from the mill.This field case study focuses solely on the latter, evaluating and documenting the sound level reduction attributed to the installation of the blankets and its

Үйлчилгээ

ball mills diaphragms

The Drum Mill TM 500 is a laboratory ball mill designed to grind large sample volumes up to 35 l. It accepts initial feed sizes of up to 20 mm and can achieve grind sizes down to 15 m by friction and impact. Hard, brittle or fibrous samples are pulverized in the 150 l drum filled with 80 kg grinding balls. Get Price.

Үйлчилгээ

Effect of operating parameters in stirred ball mill grinding of coal

1989year12month1day A study of the effect of several key operating parameters indicates the following: (1) For the type of stirred ball mill used in this investigation, the energy input is used most efficiently at low stirring speeds. At a given energy input, the mean product size decreases linearly with a decrease in stirring speed.

Үйлчилгээ

ball mills coal deficiencies bhansalitrailors in

ball mills coal deficiencies; TPS Coal Mills and Fan Performance - SlideShare. May 08, 2022 • For ball mills there is a curve linking mill capacity with the top size of coal fed to The air swept ball mill is an ideal grinding machine

Үйлчилгээ

China Coal Ball Mills, Coal Ball Mills Manufacturers,

China Coal Ball Mills manufacturers - Select 2023 high quality Coal Ball Mills products in best price from certified Chinese Coal, Metal Ball suppliers, wholesalers and factory on Made-in-China

Үйлчилгээ

Maximizing wear resistance of balls for grinding of coal

2007year9month10day Section snippets Case description. A Brazilian power plant consumes mineral coal with high ash contents to feed four turbines to generate 450 MW.Four ball mills, 4.2 m in diameter, are fed with crushed coal with maximum size of 25 mm and up to 20% humidity, to deliver the material ground to sizes less than 0.075 μm.Each ball mill is fed

Үйлчилгээ

Henan Mining Machinery and Equipment Manufacturer

» osborn ball mills gauteng » ball mill 20 ton » 20 x 34 ball mills gold » 20 ton ball mills » approximate cost of ball mills for organic synthesis barrel rotators as ball mills Ball Mills. ... ball mills coal deficiencies; barrel rotators as ball mills; extracting metal from an ore in a flow chart; Related Information. mashala coal tlb ...

Үйлчилгээ

How to Choose Ball Mill Trunnion for Cement Mill, Autogenous Mill, Coal ...

2023year5month25day When selecting a ball mill trunnion for your mill, several crucial factors should be considered to ensure optimal performance and longevity. 1. The operating conditions and environment of the ball mill play a significant role in mill trunnion selection. Factors such as temperature, humidity, and the presence of corrosive substances must

Үйлчилгээ

- цианирования в шаровой мельнице

- дробилка машина для тепловой электростанции дробилка Китай

- челюсти дробилка проката ик

- Завод камнедробилки в Монреале

- шаровая мельница Ш 50А

- инструкция по эксплуатации смд 114

- мощности угольной мельнице

- карьер дробилка размер коробка передач ч

- устройство дробилки для полимеров пластсмас форум

- стоимости проекта по производству м песка в Тамилнаду

- щековая дробилка для обводненных руд

- пластиковые формы для искусственного камня купить в ижевске

- организационная структура компании Quary

- Мельница высокого давления с суспензионными валиками YGM 95

- производственная линия